Limiting spray drift and improving coverage

Callen Thompson, Senior Extension Agronomist, Katherine

Agriculture in the Northern Territory is famous for its vast cattle stations but we know that within this landscape horticulture and hay production is often concentrated in specific areas where there is good soil and water. There is also likely to be lifestyle blocks in the same areas. In these intensive areas there is a significant risk of spray drift damaging neighbouring crops, pastures or the environment if chemicals are not applied properly.

Using spray equipment, whether it be for weed, pest or disease control, is part of most agricultural systems and the Australian Pesticides and Veterinary Medicines Authority (APVMA) ensures that chemicals are safe for use as long as the applicator follows the directions on the label.

High value horticultural crops like mangoes, Asian vegetables and sandalwood are susceptible to herbicides such as 2-4,D, which are commonly used for broadleaf or woody weed control in pasture and hay paddocks. If these chemicals are applied in-correctly, in poor weather conditions or with inappropriate equipment, they can drift onto neighbouring crops. This may cause yield loss or even death to the susceptible ‘off target’ crop, which can lead to litigation if significant damage is caused.

Even if the chemical does not land on an off target crop it may contaminate the environment. In addition, chemical that is not landing on the desired crop is wasted, effectively decreasing the rate of chemical applied, decreasing the effectiveness of the job.

By understanding weather conditions, your equipment and the product you are using, you can limit the risk of off target drift while still getting good coverage.

Coverage

Coverage is important as chemical that does not land on the target is wasted. This is effectively reducing the rate of product you are using, which can lead to reduced efficacy and low rate herbicide resistance. Products where this is especially important are insecticides fungicides and contact herbicides, especially when applying as a protective spray.

Products like glyphosate are translocated through the plant so coverage is not as important as the chemical will travel from the point of contact to the rest of the plant. Some products, like gramoxone, are extremely poorly translocated and rely on the whole plant being covered to achieve effective control.

Pre-emergent products like S-Metolachlor need good coverage as they act as a film, stopping weeds emerging through the top soil. Timing, solubility of the product and ground cover can affect the degree of chemical coverage achieved.

Droplet size

Different nozzles can give you different droplet size ranging from very fine to extremely coarse. Fines droplets are small, slow moving and highly susceptible to drift while course droplets are large, fast moving and less susceptible to drift.

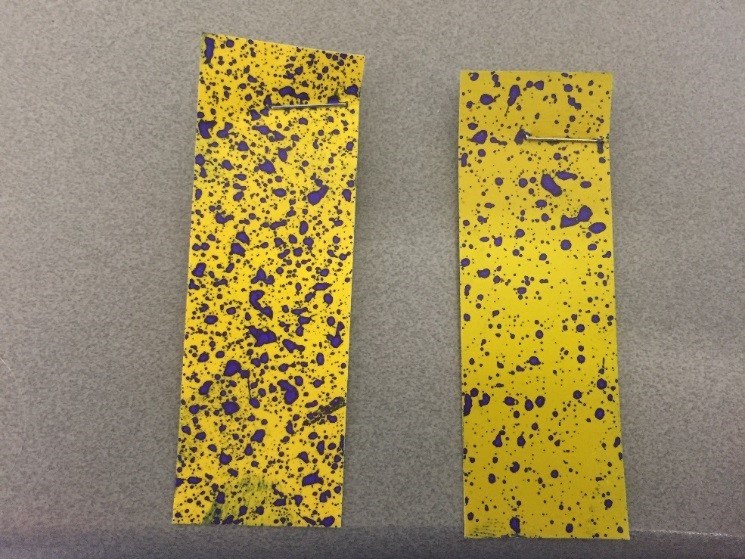

If landing on the desired target, fine and medium droplets will give a more even coverage compared to coarse droplets, unfortunately weather conditions and equipment setup can decrease fine droplet survival and increase movement off target. Good coverage can be achieved using coarse droplets if the water rate is increased. Figure 1 shows water sensitive paper comparing two spray rates, 100 and 50 L/ha using air induction nozzles. The higher water rate achieved far greater coverage.

Figure 3: 100L/ha of water on the left vs 50L/ha of water on the right. Both very coarse droplets.

Weather conditions effecting application

Weather in the Northern Territory is generally marginal for spraying. It is important we understand how weather effects spray quality and how we can manage it.

Wind

Wind can blow droplets of target, this is called physical drift. It is important not to spray when wind is blowing towards susceptible crops. Risk of drift can be reduced by using coarse droplets because larger droplets have greater velocity and are less susceptible to being blown of target. Spray when wind speed is between 3-20km/h and is not gusting (some products like 2-4,D label requires less than 15km/h). Never spray when there is little to no wind (less than 3km/h) as this can allow fine droplets to float upwards into an inversion layer (see below). When you are measuring wind speeds always measure at boom height.

Temperature

At high temperatures the weed may have shut down and not translocate the product so never spray when weeds are showing signs of stress. High temperatures can cause volatile chemicals to vaporise and lift of the target. This is called vapour drift and can happen hours after the chemical has been applied. Chemical companies recommend that you don’t spray at temperatures over 30oC.

High temperature combined with low humidity can effect droplet survival due to evaporation. Using coarser/larger droplets will decrease the effect of evaporation. Because of this relationship, understanding Delta T is very important.

Humidity and Delta T

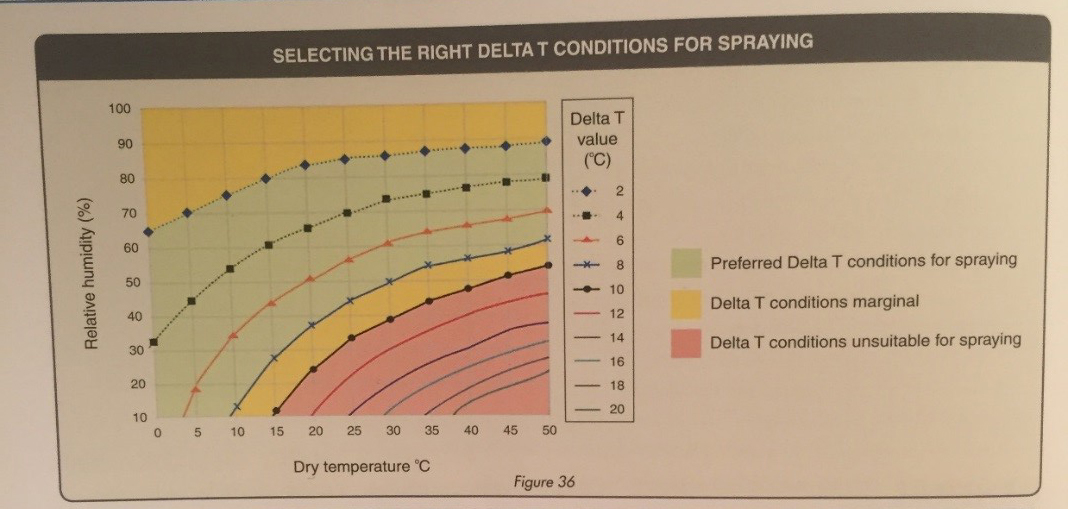

Increased humidity can reduce droplet evaporation rate. The relationship between temperature and humidity is expressed by Delta T. High Delta T (high temperature/low humidity) causes droplet evaporation and can limit the product hitting the target. Low Delta T (low temperature/high humidity) can be a drift issue as fines droplets have greater survival as they are not evaporated. The graph in figure four is a great tool to determine the right Delta T conditions for spraying. Delta T between two and eight is ideal.

Figure 4: Selecting the right Delta T conditions for spraying, Source: Jorg Kitt, Spraywise Broadacre Application Handbook, 2008

Surface temperature inversion

A surface temperature inversion is commonly known as an inversion layer, and has the potential to cause chemical drift up to 30km from the area sprayed.

Under normal conditions temperature decreases further away from the ground. In an inversion event temperature increases with height. The cool air doesn’t mix with the warm air and layers are formed. Fine droplets or vapour can be trapped in these layers and float away.

This often happens when there is low wind, high daytime temperatures and low night temperatures. Inversion layers usually occur early evening, night time and early morning. Dust, smoke and fog can indicate an inversion layer. Fine droplets are most susceptible.

Using spray equipment to limit drift and maximise coverage

Weather conditions in the NT can be detrimental to achieving good spray outcomes. There are ways to maximise the chance off chemical reaching the target by spray-rig setup and selecting appropriate nozzles.

Boom height

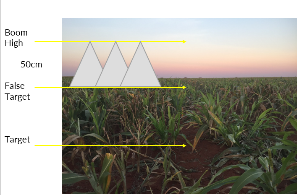

It is important to set the boom high enough that there is overlap of nozzle fans but not too high that there is potential drift. Figure six shows that 110 degree flat fan nozzles should be 50cm from the target. If there is a false target, which may be stubble or crop. The boom should be 50 cm above that. Grains Research and Development Corporation (GRDC) data suggests that raising the boom from 50cm to 75cm increases drift potential four times. Counteract this risk by increasing droplet size to reduce driftable fine droplets. This will also improve coverage as larger droplets will have greater velocity and will get through the crop/stubble canopy.

Figure 5: Speed is an important factor in spray application

Speed

Increasing speed reduces the time it takes to spray a paddock which can be beneficial when trying to get a job done before weather conditions change. Unfortunately, increasing speed can lead to wind shear and eddies, which creates increased fine droplets. Increased speed without increasing water rate can decrease coverage, particularly with a standing target.

Figure 6: Selecting boom height when there is a false target.

Water rate

Increasing water rate is the easiest way to increase coverage. If coarse droplets need to be used for drift reduction, increasing water rate can significantly reduce the issue of poor coverage generally associated with increased droplet size. Water rate can be increased without decreasing speed, if you have the correct nozzle.

Nozzle selection

There are many different nozzles but for broadacre boom spraying, the main groups used are conventional flat fan nozzles, pre-orifice flat fan nozzles and air induction nozzles. Characteristics of these nozzles can be seen in table three.

Table 3. Characteristics of commonly used nozzles (photo credit: TeeJet)

Conventional nozzles | Pre-orifice flat fan nozzles | Air induction nozzles |

|---|---|---|

|

|

|

|

|

|

The pre orifice meters flow and restricts the amount of liquid which decreases internal pressure. This leads to larger droplets. The difference with air induction is that they contain a venturi which draws air bubbles into the liquid stream. The droplets exiting the nozzle are generally course to very cause and are filled with air. This can create a cushioning effect when they hit the plant so they don’t bounce off, which can happen with large droplets from conventional nozzles.

Colours of the nozzle represent its size of the nozzle e.g. all yellow nozzles are 02 (0.2 gallons per min @ 2.8bar). The larger the nozzle, the more water it puts out. All nozzle manufacturers have charts for their nozzles. A nozzle chart allows the user to pick the appropriate nozzle for the water rate, speed and pressure the want to use.

Figure 7: Choosing the right nozzle for the job is essential

Application technology workshops

The Department of Primary Industries and Resources and NT Farmers identified the need for greater training in application technology and applied for funding from Federal Government’s National Landcare programme promoting sustainable agriculture. This funding was used to run training workshops at Douglas Daly, Katherine and Darwin. A YouTube video was also produced to demonstrate nozzle selection.

If you would like further information about improving your application practices or would like staff within your organisation to attend a spray technology workshop, please contact Callen Thompson.

Give feedback about this page.

Share this page:

URL copied!